Industrial IoT

SynCross-Industrial IoT Ecosystem is an innovative platform designed to revolutionize industrial operations by leveraging the power of the Internet of Things (IoT). The platform is fully developed by the SincoS R&D team to serve as acomprehensive solution for businesses seeking to optimize their processes, enhance efficiency, and gain valuable insights into their operations. At its core, SyncrossIndustrial IoT Ecosystem seamlessly integrates various IoT devices, sensors, and data analytics tools to create a connected environment within industrial settings.

Feature Overview

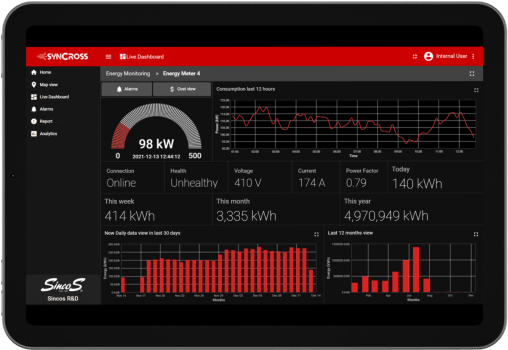

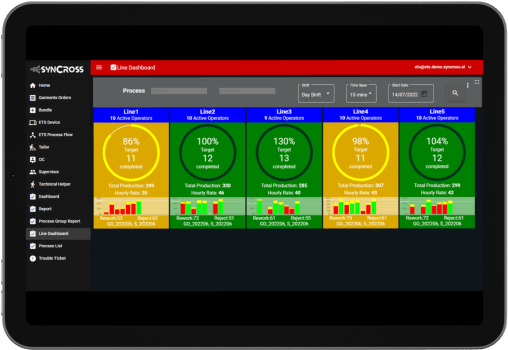

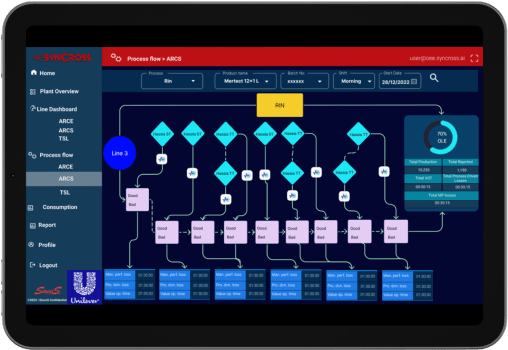

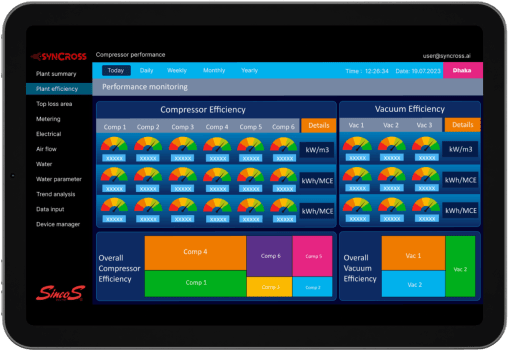

DATA ACQUISITION AND ANALYTICS

Syncross IIoT collects data from sensors on industrial equipment and systems, analyzing it to extract insights, detect patterns, and identify improvement opportunities

PREDICTIVE MAINTENANCE

Using machine learning algorithms to predict equipment failures and maintenance needs before they occur, minimizing downtime and maximizing uptime.

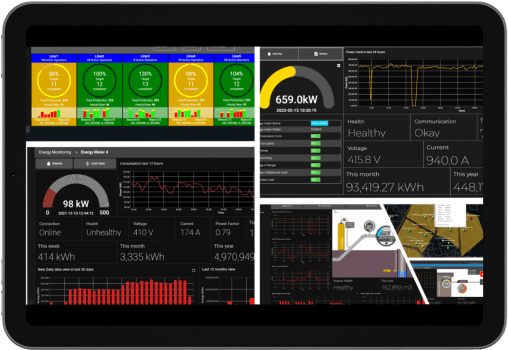

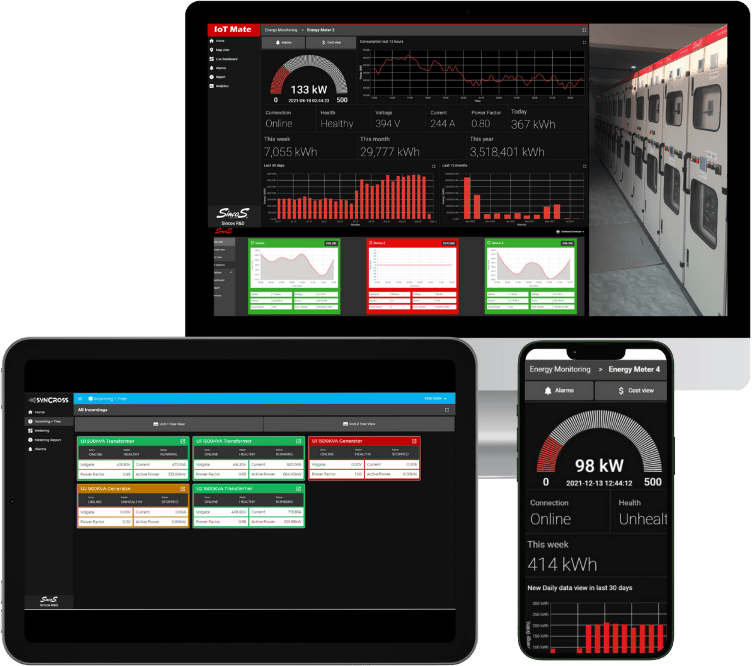

REMOTE MONITORING AND CONTROL

Allowing operators to monitor and control industrial assets from anywhere, using webbased or mobile applications

INTEGRATION WITH EXISTING SYSTEMS

Seamless integration with existing enterprise systems, such as PLC, SCADA, ERP and MES, to provide a holistic view of operations

SCALABILITY AND FLEXIBILITY

Adaptable to different industries, processes, and environments, with the ability to scale up or down as needed.

ADVANCED REPORTING

Reports can be generated hourly, daily, weekly, monthly, half-yearly, or yearly, in multiple formats including pdf andf excel offering in-depth insights into industrial operation

FAILURE PREDICTION & ALARM NOTIFICATION

Syncross IIoT includes a failure prediction feature with alarm notifications, alerting users to potential equipment failures before they occur.

FLEXIBLE DATA STORAGE OPTIONS

Choose between storing data in the cloud platform, company-owned data hub, or Syncross data center based on preferences and requirements

ENVIRONMENT & CONDITION MONITORING

Syncross allows for realtime tracking of environmental factors and equipment conditions, facilitating proactive maintenance and optimizing operational efficiency

CUSTOMIZABLE

Customizable solutions that can be tailored to meet the specific requirements of energy, utility, production, or any equipment and process needs