Industrial Automation

TAILORED SOLUTIONS TO MEET YOUR UNIQUE NEEDS

TRANSFORMING IDEAS INTO REALITY

Custom Design and Development: Our team colaborates closely with you to understand your specific requirements and chalenges. We design and develop automation solutions that are not only effective but also perfectly aligned with your business goals.

Advanced Programming: Utilizing cutting-edge automation technology, we program your systems for optimal performance. Our solutions are intuitive, user-friendly, and capable of handling complex tasks with ease.

Professional Installation: Our skiled technicians ensure a smooth instalation process, seamlessly integrating new systems into your existing operations without disrupting your workflow.

System Optimization and Upgrades: We go beyond just setting up your systems; we ensure they run at peak efficiency. Our services include system optimization and upgrades to keep your operations at the forefront of technology.

SYSTEM INTEGRATION

We specialize in integrating diverse automation systems and equipment into a cohesive and efficient operational framework. Our solutions ensure seamless communication between hardware, software, and control systems, providing a unified automated environment tailored to your needs.

Steps to Implement Industrial System Integration

- Assessment and Planning

- Choosing the Right Technologies

- Implementation and Testing

- Monitoring and Maintenance

PROGRAMMABLE LOGIC CONTROLLERS (PLCS)

Our team designs, programs, and implements state-of-the-art PLC systems that provide precise control over your industrial machinery and processes. With our PLC solutions, you can expect enhanced reliability and performance in your operations.

- Evaluation of existent or new project

- Design/Programming

- Implement

- Test/Troubleshooting

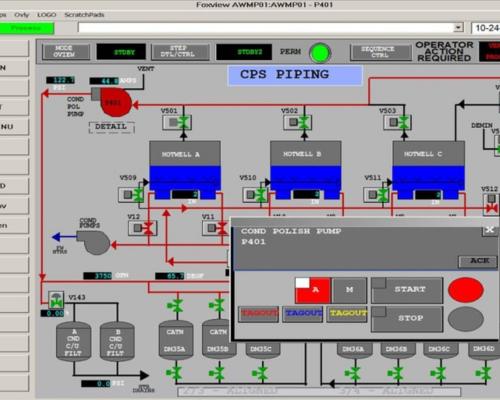

HUMAN-MACHINE INTERFACES (HMIS)

We develop intuitive HMIs that facilitate smooth interaction between operators and automated systems. Our interfaces offer real-time data visualization and controls, enabling effective monitoring and management of your industrial processes

- Identify and understand the needs

- Create a design plan & develop wireframes

- Prototype development

- Detailed design and development

- Functional and usability testing

- Install the HMI

- Monitor performance

Supervisory Control and Data Acquisition (SCADA)

Our SCADA systems provide comprehensive real-time monitoring and control of your operations. By collecting data from sensors and equipment, our SCADA solutions offer a holistic view of your industrial processes, ensuring optimal performance and quick response to any issues.

Our SCADA Service Offerings

SCADA Check

Low-cost assessment for facilities with no controls or limited/antiquated systems.

Get recommendations for improvements and estimated costs for capital planning.

SCADA Review

In-depth review for facilities with more advanced systems.

Get recommendations for immediate improvements and future capital needs.

Design & Implementation

Complete design, construction, and integration support.

Design-build or design-bid-build delivery.

SCADAServ

Scheduled, on-call, and 24/7 emergency maintenance support.

Robotics and Machine Vision

We integrate Vision Systems and Inspection Sensors using the most effective technology; providing fast, high quality and cost-effective solutions that efficiently help improve processes. Integrate advanced robotics and machine vision systems into your manufacturing processes with our expertise. Our solutions enhance precision, speed, and quality, making tasks such as assembly, inspection, and packaging more efficient and reliable.

- Vision Evaluation

- Vision Inspection

- Hardware / Software

- Design

- Reject Stations

- Vision and Inspection

- System Validation

Distributed Control Systems (DCS)

For complex and large-scale industrial processes, our DCS solutions offer centralized control and coordination. We ensure your operations run smoothly and efficiently with our robust and scalable DCS implementations.

The architectural design of a DCS includes the following:

- An engineering workstation: This is a supervisory controller for the DCS as a whole.

- An operating station: This station is used for control, operation and monitoring.

- A process control unit: This microprocessor-based controller is designed for automatic and compound loop control.

- A communication system: This system brings data from station to station and is important in distributed control systems. Typical network protocols used include Ethernet, Profibus and DeviceNet.

- Smart devices: These are any smart devices or bus technologies that are used to replace older I/O

Process Optimization

Our process optimization services analyze and enhance your industrial processes to improve efficiency, reduce waste, and increase productivity. Using advanced analytics and machine learning, we help you achieve optimal operational performance.

Here are some steps for process optimization:

- Identify the process to be improved

- Assess the process’s efficacy and determine areas for improvement

- Implement the improvements

- Test and track the updated process

- Optimize the process with automation

Maintenance and Support

We provide ongoing maintenance and support to keep your automated systems running at peak performance. Our dedicated team ensures your equipment remains reliable and efficient, minimizing downtime and maximizing productivity