Machine vision refers to the utilization of hardware and software systems that enable devices to receive guidance in their operations through the capture and processing of images. It encompasses various applications across industrial and non-industrial settings. In industrial contexts, machine vision emphasizes reliability, robustness, and cost-effectiveness, utilizing specialized cameras with digital sensors to acquire images. These images are then analyzed and processed by computer software to extract relevant information for decision-making purposes.

Some common uses of machine vision include:

- Visual inspection and defect detection

- Positioning and measuring parts

- Identifying, sorting, and tracking products

- Process control

- Robot guidance

Sincos, a prominent entity in Bangladesh, has been at the forefront of delivering Intelligent Machine Vision Systems and Scanning

Solutions since forming a strategic partnership with Cognex in 2018. This collaboration underscores our commitment to providing

cutting-edge technology solutions in the realm of industrial automation and visual inspection.

The partnership leverages Cognex’s expertise in intelligent machine vision, bringing a range of capabilities to the Bangladeshi market

through Sincos’s established network and industry knowledge. Together, we address the growing demand for robust and reliable

solutions in quality control, inspection, and automation across manufacturing sectors`

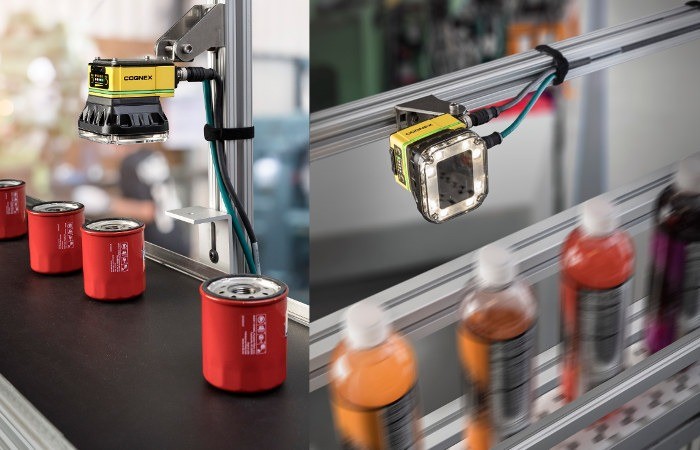

COGNEX VISION SYSTEM

Cognex In-Sight 2D machine vision systems are unmatched in their ability to inspect, identify and guide parts. These self-contained, industrial-grade vision systems combine a library of advanced vision tools with high-speed image acquisition and processing. A wide range of models, including line scan and color systems, meet most price and performance requirements.

3D VISION SYSTEM

Whether performing a single profile measurement or scanning an entire surface in 3D, Cognex has the most powerful and robust 3D machine vision tools. Manufacturers in all industries trust Cognex technology to deliver high accuracy surface feature measurements that go beyond the capabilities of 2D machine vision technology

BARCODE READERS

COGNEX DataMan series of industrial, image-based barcode readers decode 1-D and 2-D codes, from printed labels to the hardest to read direct part mark (DPM) codes, and deliver industry-leading read rates. Cognex barcode readers can help reduce costs, increase throughput, and control traceability.

We can help you to meet your strategic goals through Cognex machine vision

- Higher quality Inspection, measurement, gauging, and assembly verification

- Increased productivity Repetitive tasks formerly done manually are now done by Machine Vision System

- Production flexibility Measurement and gauging / Robot guidance / Prior

- Less machine downtime and reduced setup time Changeovers programmed in advance

- More complete information and tighter process control Manual tasks can now provide computer data feedback

- Lower capital equipment costs Adding vision to a machine improves its performance, avoids obsolescence

- Lower production costs One vision system vs. many people / Detection of flaws

- Scrap rate reduction Inspection, measurement, and gauging

- Inventory control Optical Character Recognition and identification

- Reduced floorspace Vision system vs. operator.