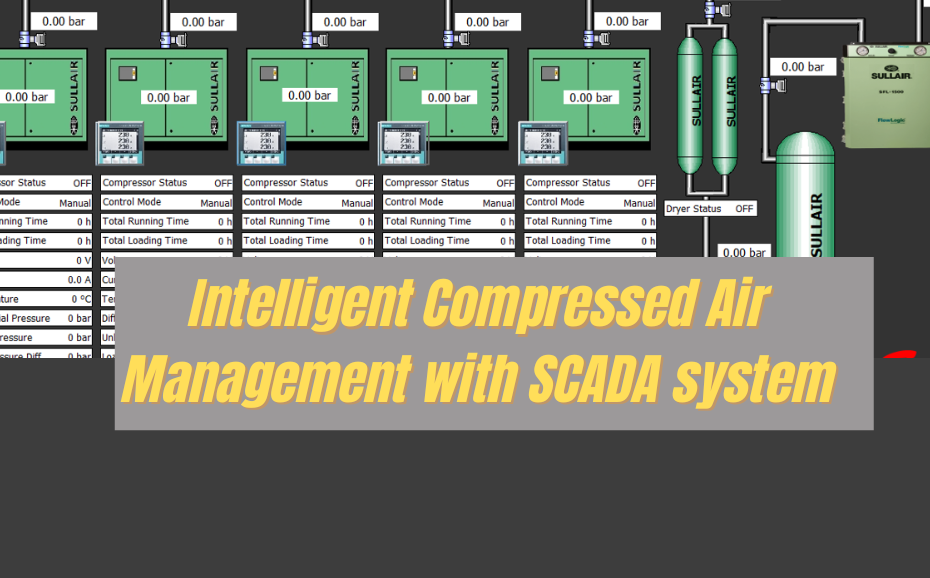

Compressed Air Management with a SCADA system involves optimizing the usage of compressed air in industrial processes. SCADA, or Supervisory Control and Data Acquisition, is a control system architecture that uses computers, networked data communications, and graphical user interfaces for high-level process supervisory management. The goal of this process is to reduce the amount of compressed air that is used, while still maintaining the required level of production. This can be achieved by identifying and eliminating leaks, optimizing the pressure and flow of compressed air, and using variable speed drives to control the speed of compressors.

SCADA systems can be used to monitor and control a wide range of industrial processes, including compressed air systems. By collecting data from sensors and using that data to control the system, SCADA systems can help to improve efficiency and reduce costs.

Some of the benefits of using an Intelligent Compressed Air Management system with a SCADA system include:

Reduced energy costs

Increased production

Improved safety

Reduced maintenance costs

Extended equipment life

Increased environmental sustainability

In the context of compressed air management, SCADA systems can monitor and control various components of the compressed air system. Here’s how it works

Monitoring compressor performance to predict maintenance needs and reduce downtime. A SCADA system can monitor the performance of your compressors and identify potential problems before they cause downtime. This can help you to schedule maintenance more effectively and avoid costly repairs.

Demand-side management to track the demand for compressed air in real-time and adjust compressor output accordingly. A SCADA system can track the demand for compressed air in your facility and adjust the output of your compressors accordingly. This can help you to avoid wasting energy by producing more compressed air than you need.

Leak detection to pinpoint the location of leaks and alert operators, facilitating quick repairs to minimize energy wastage. A SCADA system can detect leaks in your compressed air system and alert operators to their location. This can help you to quickly repair leaks and avoid wasting energy.

Energy efficiency by implementing energy management strategies, such as load shedding during non-peak times or optimizing compressor sequencing. A SCADA system can help you implement energy management strategies that can save you money on your energy bills. For example, you can use a SCADA system to shed load during non-peak times or optimize the sequencing of your compressors.

Remote monitoring and control to enable quick response to issues, adjustments to system parameters, and the ability to optimize operations from a centralized location. A SCADA system can give you remote access to your compressed air system so that you can monitor it and make adjustments as needed. This can help you to keep your system running smoothly and efficiently.

Data analysis and reporting to identify trends and patterns in compressed air usage, generate reports for performance metrics, energy consumption, and cost savings, and aid in continuous improvement efforts. A SCADA system can collect data on your compressed air usage and generate reports that can help you identify trends and patterns. This information can be used to improve the efficiency of your system and reduce costs.

SincoS: Redefining Efficiency in Compressor Air Management

SincoS team is able to select the most efficient combination of compressor units at defined working pressures. This applies to various types of rotary stationary compressors, such as Variable Speed Drive (VSD), fixed-speed, oil-lubricated, oil-free, turbo, or low-pressure units. The optimization process involves balancing unit running hours, ensuring optimal performance and energy utilization across the compressor fleet. This can lead to significant cost savings for businesses, as well as a reduction in their environmental impact.SincoS team enables LAN and SCADA system connections to any device, these controllers empower users with comprehensive control and extraction of critical data. Local visualization and analysis of energy consumption and efficiency are seamlessly integrated, providing a holistic view of the compressed air system’s performance. This flexibility allows for centralized control of compressed air systems spread across different locations within a production site, improving overall efficiency and responsiveness.

In addition, SincoS has an authorized partnership with Sullair, a brand of reliable compressed air. Sullair is a global leader in the compressed air industry, and its products are used by businesses of all sizes in a variety of industries. Sincos is a leading supplier of compressed air equipment and services and the partnership with Sullair ensures that their customers have access to the highest quality compressed air products and services.

In Conclusion, the capabilities of these systems extend beyond conventional compressor room sequence control, offering users the option to implement top-of-the-range energy optimizers. From intelligent compressor unit selection to seamless connectivity and Industry 4.0 readiness, these advancements signal a new era in the optimization of compressed air systems, contributing to both cost savings and environmental sustainability. As industries continue to evolve, embracing these technologies becomes not just a choice but a strategic imperative for staying competitive in the modern manufacturing landscape